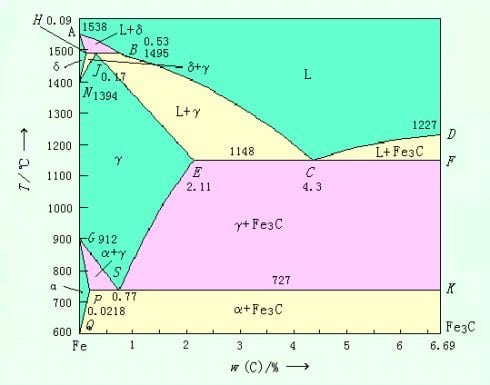

As we all know, phase diagrams can be verified experimentally. However, experimental phase diagrams require large labor and material resources. Under the conditions of high temperature, high pressure and corrosive gases involved in the reaction, they will also encounter difficulties in composition control, container selection and high temperature measurement, and the experimental determination is always limited, one-sided, unable to make a complete and comprehensive understanding of the phase diagram and thermodynamic properties systems.

Then calculating the phase diagram is a convenient solution.

He calculated the phase equilibrium of the system using thermodynamic principles and built a phase diagram. Once the phase diagram is introduced, only the thermodynamic data of some key regions and some key phases of the system’s phase diagram can be experimentally measured to optimize the parameters of the Gibbs free energy model, and the entire phase diagram can be extrapolated to build the system.

Complete phase diagram of the thermodynamic database.

As a result, the workload for the study of the phase diagram is greatly reduced, and possible experimental difficulties can be avoided. Simply put, phase diagram calculations can have 6 important benefits or meanings:

- It can be used to determine the actual phase of the diagram data and the thermochemical data itself, and their consistency, to make a reasonable assessment of the various experimental results obtained, and provide users with accurate and reliable phase diagram information;

- the metastable part of the phase diagram can be extrapolated and predicted to obtain a metastable phase diagram;

- it can extrapolate and predict multi-phase diagrams, calculate multi-phase equilibrium, and provide reference data for the design of real materials and processing technologies;

- by calculating the Gibbs free energy curve, the range of phase transition components without diffusion can be predicted;

- it can provide important information such as the driving force behind the phase change and the activity required to study the kinetics of phase transitions:

- It is convenient to obtain various phase diagrams with different thermodynamic variables as coordinates for studying and controlling the processes of material preparation and use in various conditions.

So why can we get the phase diagram by calculating the phase diagram?

The essence of the phase diagram calculation is to establish the thermodynamic models of each phase in accordance with the crystal structure, magnetic order and chemical order transition of each phase in the target system, and also to construct the Gibbs free energy expression for each phase. phase of these models. Finally, the phase diagram is calculated from the equilibrium condition.

Among them, the uncertain parameters in each phase of the thermodynamic model are obtained from the data on the phase balance and thermodynamic properties presented in the literature and optimized with the phase diagram calculation software. Based on the obtained thermodynamic parameters of low-component systems (usually binary and ternary systems), the phase diagram and thermodynamic information of a multi-component system can be obtained by extrapolating or adding a small number of multidimensional parameters. In general, we control the temperature, pressure and composition when processing the material. Therefore, we choose the Gibbs free energy as a model function when calculating the phase diagram.

For a system with a certain material exchange of energy with the outside world (closed system), a process with constant temperature and pressure always goes in the direction of decreasing Gibbs free energy, and the total Gibbs free energy of the system is the lowest in equilibrium. The chemical positions of the constituent elements in the phases are the same. If we know the free energy composition curve at all temperatures, we can calculate the phase diagram by finding the minimum free energy or the equivalent chemical bit of the solution. To calculate the phase diagram, we need to know the metastable part of the free energy curve. , the free energy of the metastable configuration of a pure element, and the metastable phase transition point.

The process of optimizing and calculating the phase diagram can be simply divided into five steps:

- Collection and evaluation of experimental data. The purpose of the evaluation is to evaluate the accuracy of experimental data based on the experimental methods used by the authors and to select experimental data that are consistent with thermodynamic principles and are relatively more reasonable.

- Choice of free energy model. According to the phase structure, a reasonable model is chosen and can be verified by extrapolating the multivariate system.

- Use of measured phase diagrams and thermochemical data for optimization of uncertain parameters in the Gibbs free energy expression; then use the appropriate algorithm and the corresponding computer program to calculate the phase diagram on the computer according to the phase equilibrium conditions.

- Comparison and analysis of calculation results and experimental data. If there is a large difference between them, adjust the parameters to be determined, or reselect the thermodynamic model, and then run the optimization calculation until the calculation results fit most of the phase diagram and thermochemical data within the experimental error range.

- After optimization, all phase diagrams and thermodynamic data are combined by the thermodynamic model into a self-consistent whole and finally stored in the model parameter to form the thermodynamic database of the phase diagram. Sophisticated software for calculating the phase diagram is now available. which can perform phase diagram calculations.

Phase diagram software is essentially a combination of thermodynamic models and computational principles with large-scale numerical calculations and powerful computer processing functions. It can not only perform multi-dimensional and multi-phase equilibrium, but also give various forms of stable and metastable phase diagrams. Other parameters that are closely related to the preparation and use of the material can be obtained. The main functions and features of commonly used software for phase diagram thermodynamic calculation (Thermo-Calc, Fact Sage, Pandat, Jmatpro) are as follows.

Here is a short list of their respective characteristics1.

Thermo-Calc Software The Thermo-Calc software has become a complete data system, a powerful feature and a relatively complete structural calculation system. It is a thermodynamic calculation software that enjoys a good reputation in the world. The Thermo-Calc software allows you to perform phase balance calculations (such as liquidus and solidus temperatures, composition and proportions of each phase, etc.), phase diagram calculations, and thermodynamic calculations. Thermodynamic data can also be tabulated and calculated. The thermodynamic reaction function is changed and the driving force, the phase balance of the chemical system being evaluated and the phase transition, as well as various phase diagrams are drawn using an automatic drawing program.

Fact Sage Software Fact Sage software is a combination of ChemSage / SOLGA-SMIX two thermochemical software packages. It has the advantages of rich database content, powerful computing functions and easy management on the Windows platform. In addition to multivariate multiphase balance calculation, Fact Sage software can also calculate and draw phase diagrams, dominant area maps, potential pH diagrams, thermodynamics optimization and map processing. Fact Sage software applications include materials science, pyrometallurgy, hydrometallurgy, electrometallurgy, corrosion, glass, incineration, ceramics, geology, etc.

The Fact Sage 5.5 database includes:

- compounds;

- an oxide database containing 20 elements;

- molten salt data containing 20 cations and 8 anions;

- Extensive database containing common alloy systems such as Pb, Sn, Fe, Cu, Zn, etc.

- Specific databases for specific industrial processes such as electrolytic aluminium, paper industry and high purity silicon .

In addition, Fact Sage can also use other well-known international data bases such as SGTE, and provide users with the ability to create private databases.3, Pandat software. The biggest advantage of the Pandat package is that even if the free energy function has several low points in a certain range of components, users who do not have phase diagram calculation expertise and calculation skills can do without setting initial values. Using the Pandat software, it can also automatically search for the stable balance of multi-phase multi-phase systems. The main features of the Pandat software include calculations, editing, and advanced features.